Hot runner solutions can replace traditional cold runner to conquer some product and molding issues. In addition, it can reduce wasted material and energy consumption to realize “Green Moldingâ€.

However, the mechanism is very extensive and mysterious inside such complex system. Flow imbalance, dead spot, and no-uniform heating are the significant issues in hot runner system development. More severely, material degradation occurs due to overheating and ultimately affects product quality. As a result, how to maintain melt temperature is the key and it is closely related to geometric design for the entire system and heating control methods.

YUDO, the world leading suppliers of hot runner systems for the injection molding industry, is No.1 in global market share. YUDO has found itself requiring a more advanced and accurate CAE system that would help avoid potential manufacturing problems from the point of problem’s root, and shorten the delivery time to customers. After serious evaluation, YUDO decided to globally introduce numerous Moldex3D software seats as their standard mold design verification and optimization tool in 2010 to help improve their product development, including Korea headquarters and subsidiaries all over the world. Through continuous design process improvement, Moldex3D helped reduce design time and cost, which largely increased YUDO’s competitiveness and leadership.

“CAE is not new to YUDO. However, with the more and more challenging marketing and customer demands, technologies which can ensure the better quality, cost performance, time to market, and etc., are always what we would absolutely look for. We selected Moldex3D because it offers a better approach for more advanced and accurate engineering analysis technologies on the verification and optimization of hot runner system mold development, especially for true 3D analysis technology and private HPC cloud.†said Francis Yu, the chairman of YUDO.

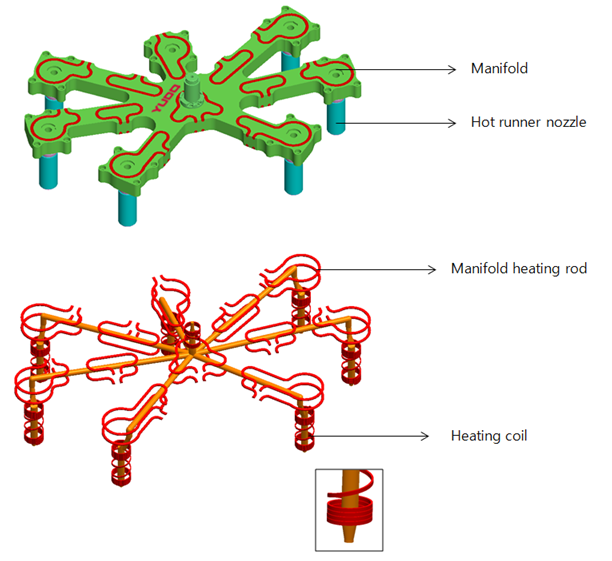

Moldex3D supports building the whole hot runner system into simulation

Moldex3D supports building the whole hot runner system into simulation

Chip IC Leadframe High Precision Stamping Die

Chip Ic Leadframe High Precision Stamping Die,High Precision Continuous Mould Customisation,Custom Metal Stamping Dies,High Precision Metal Stamping Dies

Artisan Precise Molds co.,Limited , https://www.artprecise.com